POS 10

POS 10 (to be released October 1, 2018) is the newest version of our precipitator operations software. In response to our customers depleting knowledge at the plant level, we focused development on simplicity, data availability, and alarms. The highlights of POS 10 are below!

Enhanced Analytics and Navigation

- Redesigned historical data viewer – New look to the historical data viewer, including more room for wide graphs and more information in the legend

- Improved Notes – Ability to attach notes to events in trends; in one place you can see the cause and resolutions for changes

- Easily trend values from the tag browser — Easily select tags to include in trends, and jump right to any page by referencing a selected tag

Ease of Operation

- Redesigned notes – Can now see trend notes and operator notes in a single blended display, search notes, and add comments to existing notes

- Ability to run POS as a service – POS can run without a user logged in, which is useful where security policy forbids leaving a logged-on user on a server or workstation

- Improved CIP driver – Auto-attempt to re-establish communication

- Access Improvements – Ability to login with your domain account instead of a separate login

- Anywhere Client – Provides a consistent and secure full workstation experience on modern computers, phones, and tablets

- Improved Help – Help is integrated into the application

Redesigned Alarm Interface

- Simple navigation between alarms, pages, and trends – Jump right to any page from an alarm notification or plot the tag from which the alarm was generated

- Improved Notes – Ability to add notes to alarms, and add comments later

- Alarm shelving – Ability to pause alarm notifications for a specified period of time without disabling the alarm, good for pausing alarms while troubleshooting the issue or performing maintenance

- Ability to aggregate alarms – Can help to determine the frequency of alarms and to make appropriate changes

- Improved alarm interface – Use a combination of text, symbols, color, and sound to best meet the needs of your team

- New ‘Alarm Details’ dialog – Provides a complete overview of each alarm’s configuration, history, and notes

- Improved alarm tools – Can require operators to add notes when acknowledging, shelving, or un-shelving alarms

Aren’t Already Familiar with our Precipitator Optimization System?

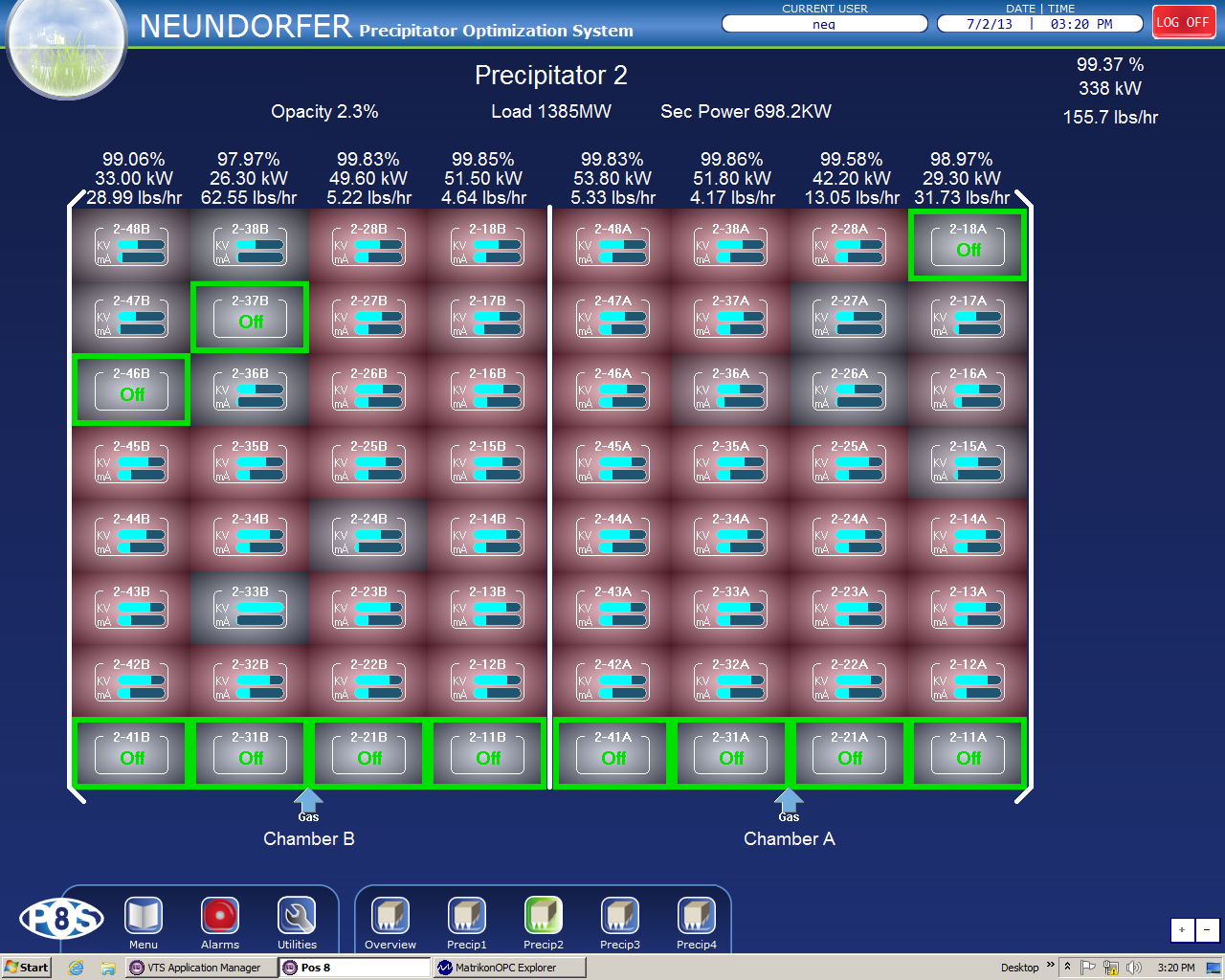

Our Precipitator Optimization Software (POS) is loaded with powerful tools to help you maintain compliance, effectively troubleshoot performance issues, and set-up conditional operating parameters to maximize performance over time and throughout production or process changes. The troubleshooting capabilities allow plant personnel to identify control issues through software. The software can be fully integrated with voltage controls, high frequency T/R sets, rapper controls, hopper evacuation systems, gas conditioning systems, purge air systems, and sorbent injection systems. This connection allows you to troubleshoot and optimize performance through using the data available from the process, precipitator, and ancillary systems.

POS can help you use data to

- Improve collection efficiency of equipment

- Plan outages

- Troubleshoot equipment and performance

- Maintain compliance

- Auto adjust operations to process conditions

- Save auxiliary power

- Compensate for the loss of knowledge at the plant