Transform Data into Improved Performance.

Often, it can be difficult to put the abundant amount of data to use, solving problems and optimizing equipment. Our data integration capabilities can help. Our systems combine data from disparate sources within the air pollution control system to drive meaningful actions. An example of this is our Precipitator Optimization Software, which combines precipitator feedback, process data, and emissions feedback to direct operational changes, troubleshooting, and outage activities. The implementation of our software is customized to your plant, challenges, and objectives. Let us help you put your data to work.

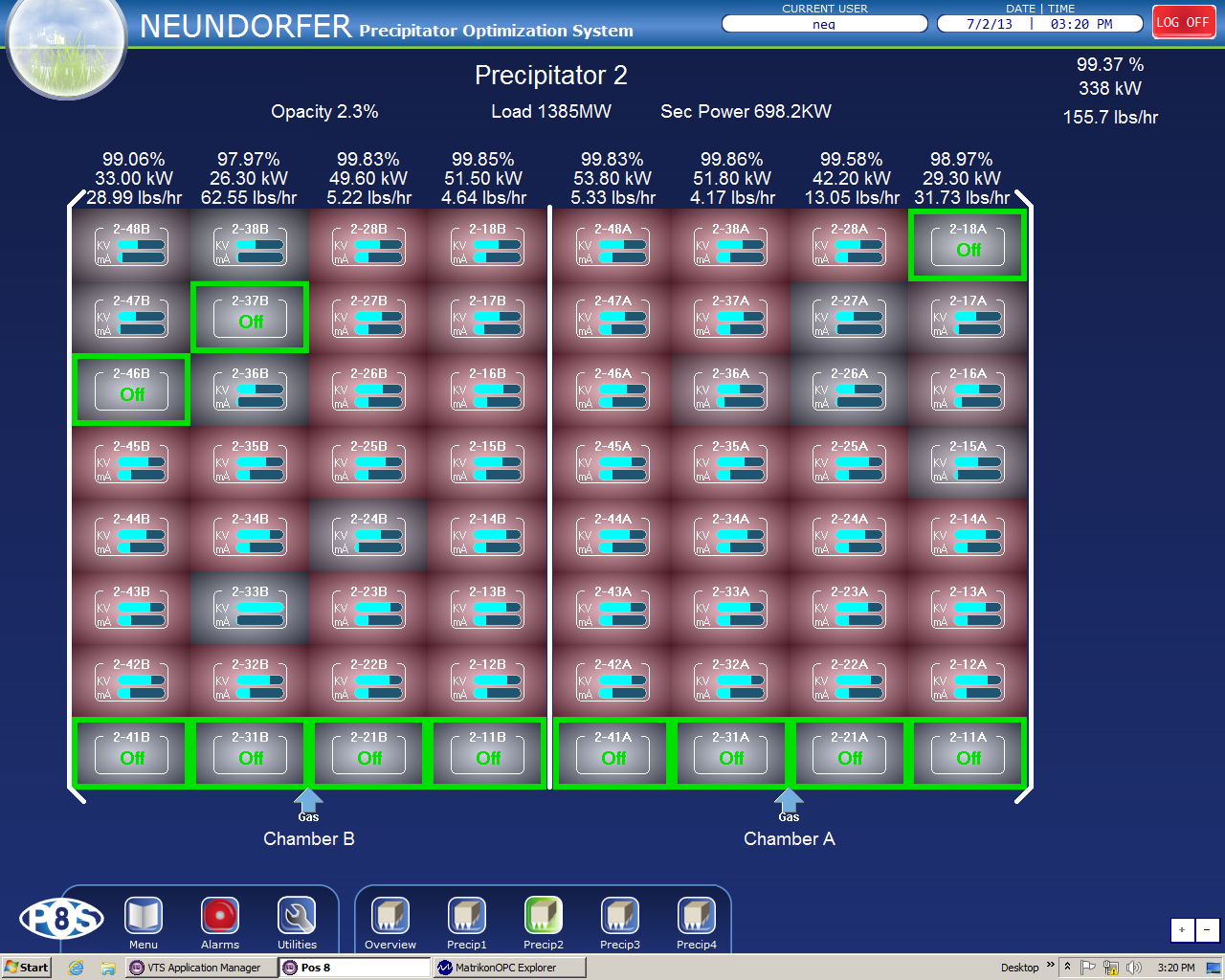

Precipitator Optimization System

Our Precipitator Optimization Software (POS) is loaded with powerful tools to help you maintain compliance, effectively troubleshoot performance issues, and set-up conditional operating parameters to maximize performance over time and throughout production or process changes. The troubleshooting capabilities allow plant personnel to identify control issues through software. The software can be fully integrated with voltage controls, high frequency T/R sets, rapper controls, hopper evacuation systems, gas conditioning systems, purge air systems, and sorbent injection systems. This connection allows you to troubleshoot and optimize performance through using the data available from the process, precipitator, and ancillary systems.

Baghouse Cleaning System

Neundorfer provides a total system approach for optimizing baghouse operations and bag life. By monitoring and integrating baghouse operations, the dusts collectors will capture pollutants more effectively, reducing energy consumption and achieving maximum filter bag life. Read more about the baghouse cleaning system.

SmartAsh

SmartAsh is a proactive system that works to avoid high hoppers, improve precipitator/baghouse and equipment performance, optimize hopper evacuation, and reduce costs. This means that you have fewer production restrictions, fewer emission excursions, and reduced system wear and energy use..

PLC Integration

Neundorfer provides total turnkey PLC integration services for a variety of applications. Our engineers can help you design and implement a customized control system that meets your needs. Our application experience includes gas conditioning systems, sorbent injection, precipitator rapping, baghouse control, boiler soot blowing and various process systems. Integration capabilities include software interfaces and optimization.

Files & Resources

- Page

- Transforming Data into Improved Performance & Reduced Costs

- View Page

- Page

- Baghouse Integration Dramatically Reduces O&M Costs

- View Page

- Page

- Smart Use of Data Improves Diagnostics, Optimizes Performance

- View Page

- POS Software Overview

- View Document

- POS 9 User Manual

- View Document

- SmartAsh Feature Sheet

- View Document

- SmartAsh White Paper

- View Document

- SmartAsh Testimonial

- View Document